|

|||

|

|

|||

|

Products

Dal Mill Driers

UNITHERM’S air heating system is designed specifically for mass Industrial batch drying of pulses.It’s superior design, efficient performance and high fuel economy makes it a better buy than any other heater-drier of its kind to achieve much lower drying costs. The unit is easy to install, simple to maintain and highly economical to operate.

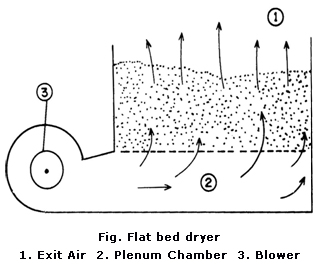

The design is suitable for a maximum temperature of clean hot air at 900 C. Principle: Convection Drying :

Heated Air Drying: Since the drying involves both heat and mass transfer operations simultaneously, the entire system has been properly designed, taking into consideration a large amount of factors like, optimum air temperature suitable for drying, air flow rate, air pressure, air velocity required, total perforated area available for air flow, total weight of the pulses to be dried, initial & final moisture contents, dimensions of the bin, height of the stacked pulses, etc. The drying system mainly consist of

Construction: The main advantages are:-

The Hot Air Generator is Oil or wood/ solid fuel fired medium air temperature hot air generator, which is very compact in construction of vertical design, with External bottom furnace. The main constituents of oil fired hot air generator are the M.S. inner & outer casings (inner S.S. casing optional) which also act as the combustion chamber. The main body of the Generator is of sturdy Construction made out of heavy gauge steel and Structure. The body is painted with epoxy paint to combat corrosive industrial atmosphere. A special, anti drip design, high efficiency, imported burner of Riello (Italy) make with low noise blower and fuel oil pump ensure almost smokeless and silent operation and reduces the downtime and maintenance problems greatly. Due to it’s unique design & efficient mixing of air & fuel, the combustion efficiency & hence the efficiency of the hot air generator is also increased. Forced Draught Blower

Low Operating Cost: Trouble – Free Operation: Clean (Uncontaminated) Hot Air can be obtained without any intermediate medium such as steam, water or oil and hence cost oriented problems such as low heat transfer efficiency, costly piping, water treatment, Boiler attendant, Indian Boiler Regulations, etc, can be done away with by installing Unitherm’ oil fired Hot Air Generators which have the following salient features.

Salient Features:

|

||

| Copyright 2008 Unitherm Engineers | All Rights Reserved | Site designed & mainted by | Kunal Internet | Sitemap | |||