|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Products

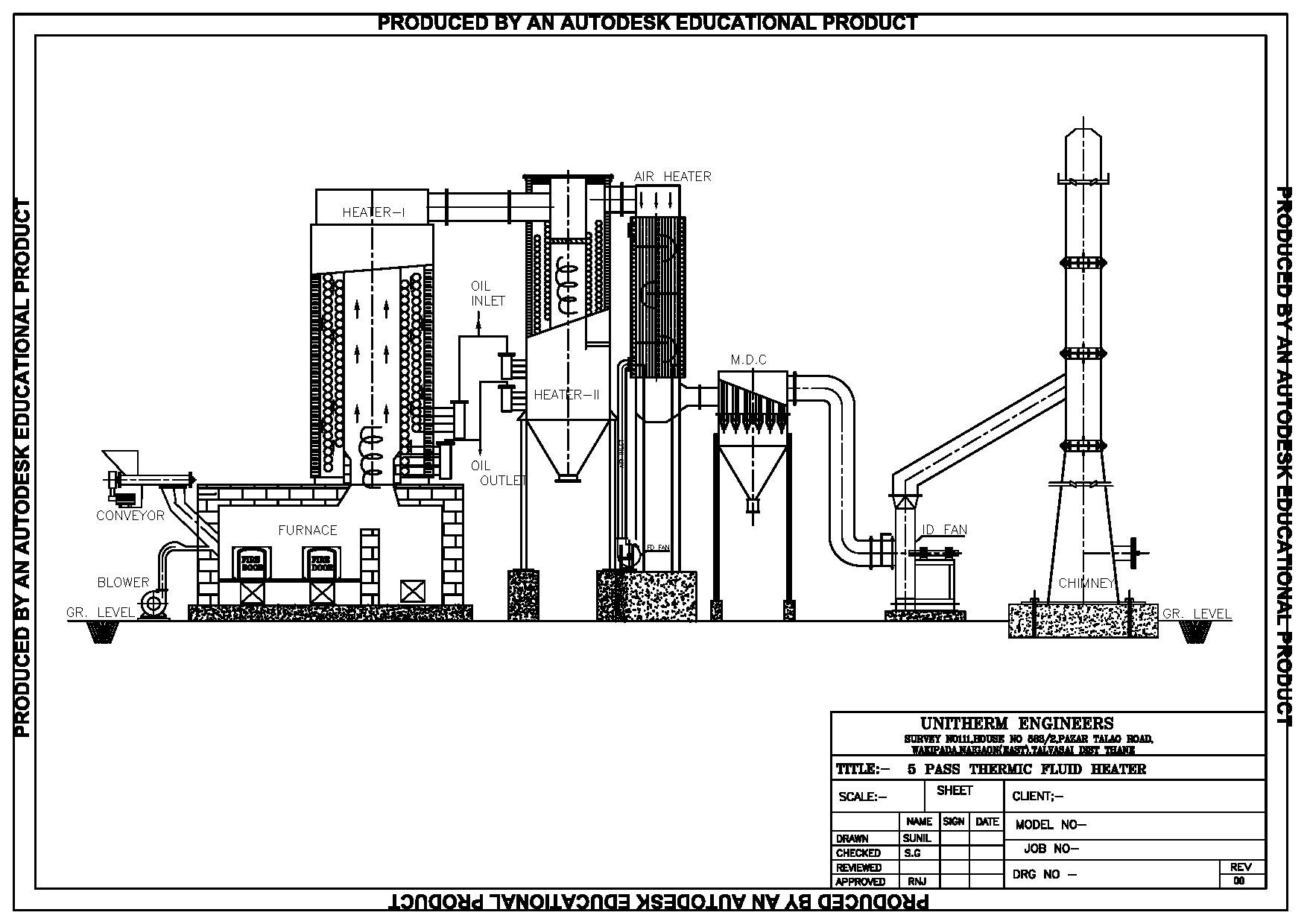

Process Heating > UNITHERM´S FIVE PASS SOLID FUEL FIRED THERMIC FLUID HEATER

UNITHERM´S FIVE PASS ECONOMICAL SOLID FUEL FIRED THERMIC FLUID HEATERCapacitiess – 10 lac Kcal to 80 Lac Kcal/Hr

DESIGN: The Unitherm system is a closed loop heating system operating at near atmospheric pressure with temperatures as high as 3000C .The System comprises of closed loop circulating of hot mineral oil through the user equipment for process heating and the return oil is reheated in the Thermic fluid Heater. There are two separate heating sections, namely Radiant & Convective Heat exchangers. The expansion cum dearation tank ensure pressure less and vapor free system. The Thermic fluid heater is of VERTICAL construction with a large diameter helical coil Placed directly on top of the combustion furnace. This ensures that the intense luminous heat of the flame is fully utilized. This is the first, Radiative section comprising of the first pass of hot flue gases.

These gases from radiant coil are then made to pass through a second, convective heat exchanger. This is made of twin concentric helical coils, placed inside a sturdy M.S. shell having three distinct passes of hot gases in the convective section where maximum amount of heat is extracted from the flue gases. The gases are then made to pass through the Air prehater & Mechanical dust collector, on way to the chimney through I.D.Fan. A generously designed refractory lined external furnace is provided to ensure high furnace volume and grate area and can ensure rated output on low-grade coal and can easily burn most other fuels such as Lignite, Paddy husk, Fire wood, Bagasse, etc, without any modifications. The Safety controls and instrumentations provided ensure completely safe operation and provide Audio Visual Alarm and cuts off the combustion in case of abnormal operating Conditions.

Coal Consumption in Kgs/Hr based on GCV of Coal 5500 Kcal/Kg |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Copyright 2008 Unitherm Engineers | All Rights Reserved | Site designed & mainted by | Kunal Internet | Sitemap | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||