Products

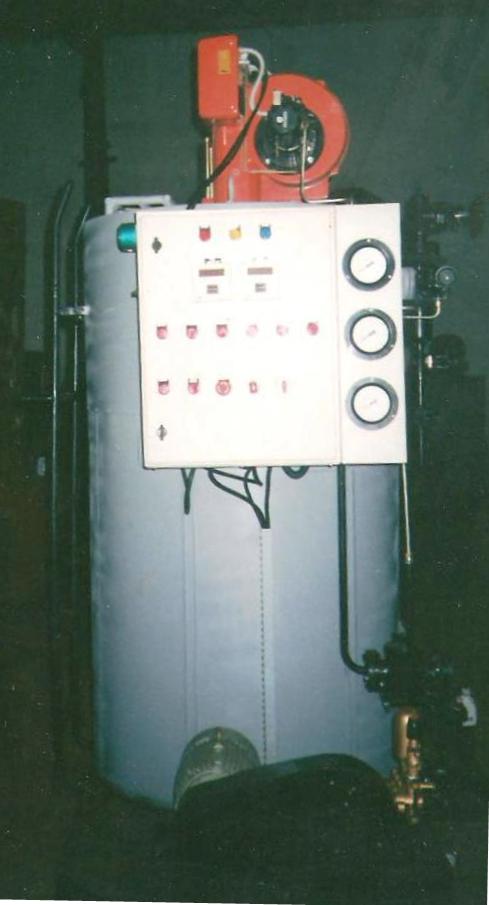

Process Heating > 4 PASS ECONOMICAL L.D.O. FIRED NON IBR STEAM BOILERS

Capacitiess – 50 Kgs/Hr to 1250 Kgs/Hr

DESIGN: Oil/Gas/LPG fired Four pass Design

UNITHERM’S Non IBR Design Boilers are most economical to use & pocket friendly for

installation. The Unitherm fully automatic Non IBR Boilers comprise of machine wound,

specially designed concentric helical coils placed inside a sturdy M.S.shell. The system

comprises of three distinct passes of the flue gases in the Boiler & the non-pressurised heat

recovery unit with heat Optimiser constitutes the fourth pass, maximizing the efficiency.

Design available in all the fuel options & also with dual fuel Burner with a simple changeover

switch.

A special, anti drip design, high efficiency, imported burner of Riello (Italy) make with low

noise blower and fuel oil pump ensure almost smokeless and silent operation and reduces

the downtime and maintenance problems greatly. Due to it’s unique design & efficient

mixing of air & fuel, the combustion efficiency & hence the efficiency of the Boiler is also

increased. The connected load is also much lower compared to any indigenous burner

resulting in sizeable power savings.

The generously designed inner combustion chamber ensures large furnace volume and

hence less heat load per unit volume, thereby increasing the life of the coil. The Safety

controls and instrumentation provided ensure completely safe operation and provide Audio

Visual alarm and cuts off the ignition system is case of abnormal operating conditions.

The Safety controls and instrumentations provided ensure completely safe operation and provide

Audio Visual Alarm and cuts off the combustion in case of abnormal operating

Conditions.

| Product Feature | User Benefit |

| Four Pass Design | High efficiency, Low fuel cost |

| Instant steaming | Ideal for Intermittent operations also |

| Non IBR Design | Lower Investment, No cost of IBR

Approvals & yearly passing |

| Ready to use Packaged

design | Faster Installation & commissioning, no hidden

costs |

| Minimum foot print area | Lower floor space required |

| Easy access for maintenance

& cleaning | Ease of operation & Maintenance |

| Coil made from 9 Gauge, 3.66

mm Boiler Tubes | Longer Coil life |

| Higher Heat transfer area per

Lac Heat Output | Ensures rated output

Longer Coil life |

| Multiple safety features | Safe & trouble free operation through the life of the Heater |

| MODEL |

|

SPR 1 |

SPR 2 |

SPR 3 |

SPR 4 |

SPR 6 |

SPR 8 |

SPR 10 |

SPR 12 |

| OUTPUT F& A1000C |

KGS/HR |

100 |

200 |

300 |

400 |

600 |

800 |

1000 |

1250 |

| LDO

CONSUMPTION |

KGS/HR |

6 |

12 |

18 |

24 |

36 |

48 |

60 |

73 |

LDO Consumption in Kgs/Hr based on GCV of LDO 10500 Kcal/Kg

| Sr. No. |

Safety Description |

Controlling Instruement |

Remarks |

Safety Interlock |

| 1 |

Steam Pressure reaches HIGH set point |

Pressure Switch |

Normal Operation |

Boiler Cuts Off |

| 2 |

Steam Pressure High |

Safety Valve |

Mechanical safety |

Valve Blows off |

| 3 |

Flame Failure |

Photocell |

Normal Operation |

Purging & Restart* |

| 4 |

Flame Monitoring |

Sequence Controller |

Normal Operation |

Purging & Restart* |

| 5 |

Steam Temperature High |

Digital Temp Controler |

Abnormal Operation |

Burner Cut-off & Hooter |

| 6 |

Stack Temperature High |

Digital Temp Controler |

Abnormal Operation |

Burner Cut-off & Hooter |

| 7 |

Blower motor Overload |

MCB |

Abnormal Operation |

Burner Cut-off & Hooter |

| 8 |

Pump motor Overload |

MCB |

Abnormal Operation |

Burner Cut-off & Hooter |

| 9 |

No Water Flow |

Level Sensor |

Abnormal Operation |

Burner Cut-off & Hooter |

| 10 |

Blow down Valve Open |

Limit Switch |

Abnormal Operation |

Burner Cut-off & Hooter |

| 11 |

Excess pressure built up |

Spring Loaded safety Door |

Mechanical Safety |

Excess Gases Released |

| 12 |

Excess Pump pressure |

Surge Supressor |

Mechanical Safety |

Releases Excess Pressure, prevents Damage |